Private case

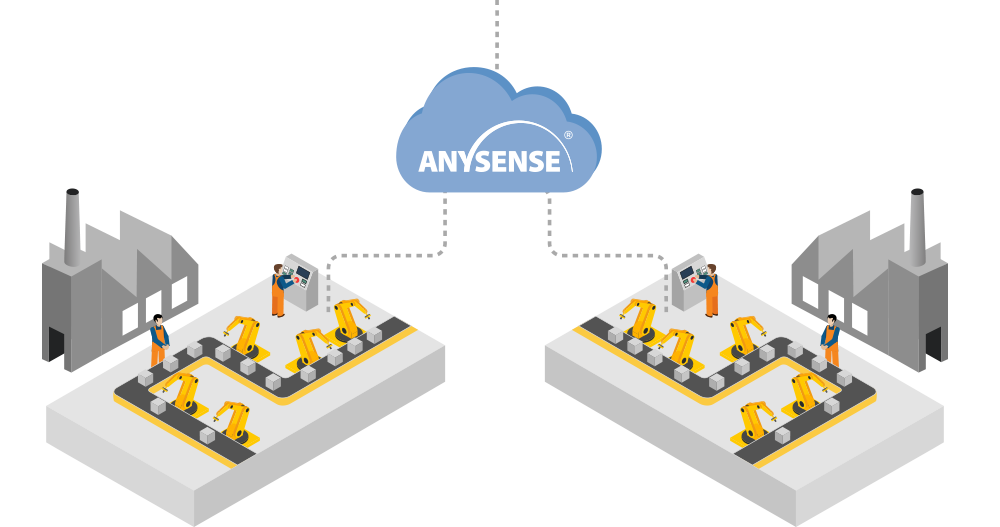

Compile the data collected from the factory automation(FA) system or the factory production on-site device then send instantly to Cloud. In collaboration with the analysis infrastructure, help to improve the business efficiency. Also FA and IoT are cooperating in the factory and improve more productable machine control and the condition of the operation.

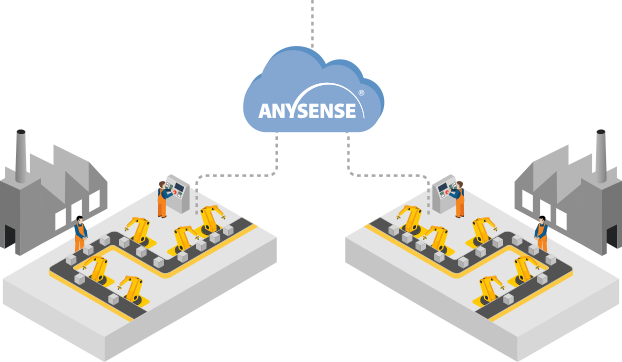

Improvement of line productivity in factories and plants

ANYSENSE accomplishes analysis, visualization and simulation in order to improve the productivity in factories and plants

The contents of “Utilize”

-

Statistical analysis (Past)

・Equipment/People

productivity

・3D Playback

・Production line and

power statistic of equipment -

Visualization (Present)

・Equipment/People

productivity

・Displaying operational

status such as 3D

・Production line/Power statistic

information of equipment -

Control simulation (Future)

・Failure prevention

・3D simulator

・Power contro

machine and people High speed and

mass transmission

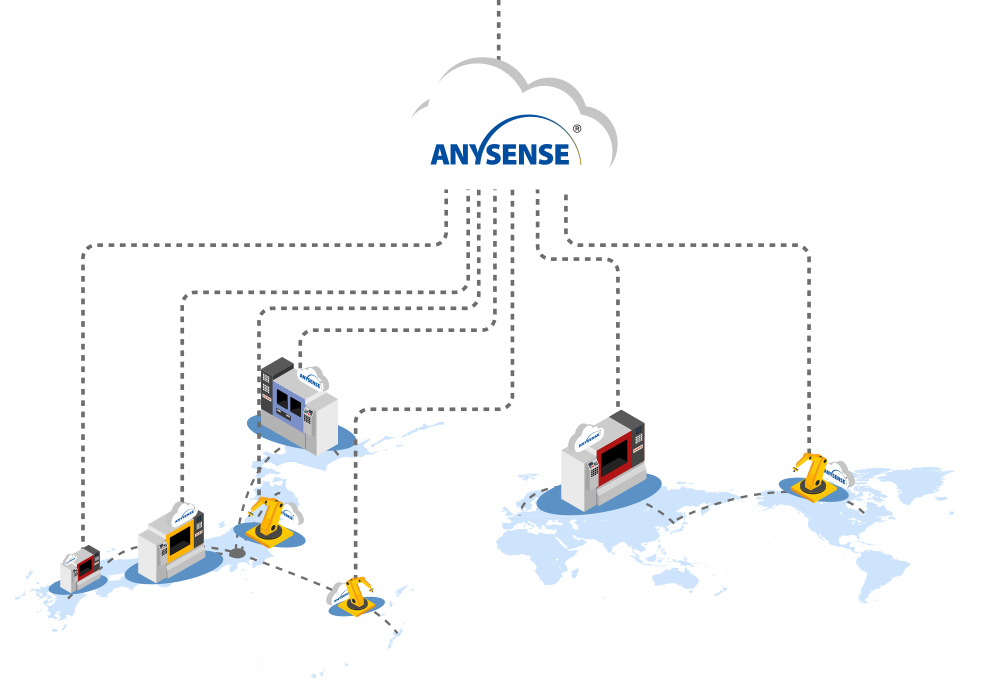

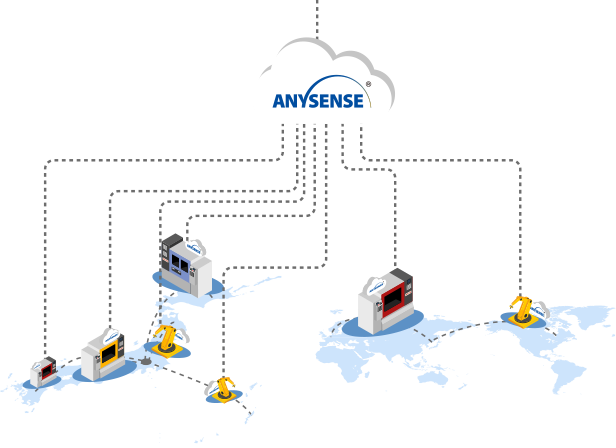

Remote maintenance for products

Provide remote maintenance and preventive maintenance in both overseas and Japan aftermarket. Due to this, we aim to improve the service and reduce the labour cost in the field service.

The contents of “Utilize”

-

Remote maintenance

・Remote monitoring

・Abnormality detection -

Preventive maintenance

・Remote maintenance

・Predictive detection

connection of MVNO Possible to install only software.

(Conditions may apply) Support World Wide